Listen to the audio version of this article. Duration: 10 minutes.

Due to their unique features, resulting from the use of proprietary production processes and raw materials, FENIX® surfaces are among the most innovative in terms of environmental sustainability, lending themselves to a wide range of applications, from various types of furniture to interior design, and even industrial design products.

MATERIAL LIBRARY AT FENIX SCENARIO

IN MILAN, ITALY

FOTO: FEDERICO VILLA

The issue of the environment is now central, due to the negative impact humans have on the planet in terms of pollution and excessive consumption of energy, water, and land, resulting in a direct effect on climate change. The growing awareness around this issue also influenced the world of interior design, to the extent that in recent years, there has been talk of sustainable interior design. This translated into an approach to interior furnishing that takes into account the environmental, social, and economic impact of design choices. This means creating interior spaces that are environmentally conscious through the use of sustainable materials, envisaging waste reduction, and the efficient use of resources. This may also involve the use of low- energy lighting systems, the adoption of water-saving devices, and adapting natural lighting to reduce electricity consumption. Some principles of sustainable interior design further include the use of quality and more durable furniture, thereby reducing waste and obsolescence.

Sustainable materials and interior design

TABLE IN FENIX® GRIGIO ARAGONA AND BLU SHABA

FOTO: NATHALIE KRAG

The main aspect of sustainable interior design, however, concerns the use of sustainable materials. These are defined as materials that are produced in an environmentally conscious manner, minimising their environmental impact throughout their lifespan, and that can be recycled or safely disposed of at the end of their lifecycle. These materials are subjected to international standards through various organisations, which provide guidelines and certifications to assess their impact on the environment. In the world of interior design, one of the most sustainable materials today is FENIX, a product created by Arpa Industriale in 2013. It has now become an open system encompassing innovative surfaces and solutions designed for interior furnishing and installations. The FENIX range comes in three versions - FENIX NTM®, FENIX NTM® Bloom, and FENIX NTA® - ideal for both horizontal and vertical applications in kitchens, tables, bathrooms, doors, and any furniture element, in addition to a multiplicity of other market segments. FENIX is part of the laminates family, one of the most common surface materials for furniture, countertops, and wall finishes in kitchens and bathrooms, obtained by pressing multiple layers of paper impregnated in thermosetting resins. Its strongpoint is the high resistance to various mechanical and chemical stresses to which it is subjected: impacts, heat, stains, scratches, or abrasions...

X-KIN, a recent addition to the FENIX® family, was developed specifically for wall coverings and cladding of structural elements for interior design. It is a flexible material which can be applied like wallpaper. Like the entire FENIX® family, it is exceptionally opaque, soft to the touch, fingerprint-resistant, and has excellent colour resistance to light.

FENIX® X-KIN GRIGIO BROMO / COURTESY OF ARPA INDUSTRIALE

Why FENIX is FENIX

BATHROOM VANITY BY LEM ARCHITETTURA IN FENIX NTM® BLOOM AZZURRO NAXOS / COURTESY OF ARPA INDUSTRIALE

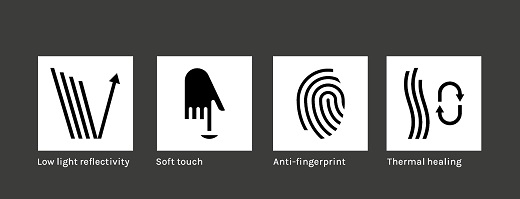

The result of years of research, FENIX® is made with next generation acrylic resins, hardened and fixed through an Electron Beam Curing process - which confers it its distinctive characteristics. Among these is the low light reflectivity that makes the surface extremely matte, anti-fingerprint, and pleasantly soft to the touch. The exceptionally matte appearance of the surface stands out as unique among other laminates, to the extent that Arpa Industriale can be credited with igniting the matte trend in interior design and significantly contributing to its widespread adoption and success.

Its main property is the possibility to thermally repair micro surface scratches. Not surprisingly, the name FENIX® is inspired by the legend of the Phoenix, the mythical bird capable of rising to new life from its own ashes.

The FENIX® family

KITCHEN BY LEM ARCHITETTURA IN FENIX NTM® BLOOM ROSSO ASKJA / COURTESY OF ARPA INDUSTRIALE

With respect to FENIX NTM® products, the firstborn of the FENIX® family, FENIX NTM® Bloom products stand out for their core, made with a thermosetting resin that uses lignin, the second most abundant natural polymer in the world after cellulose. This allowed for a significant reduction, namely 50%, in the amount of phenol.

The Bloom technology, developed by Arpa after more than seven years of intense research work, is applied across the range to the “core” of Arpa laminates. Similarly, FENIX NTA® shares the same properties of the FENIX® family but distinguishes itself by the presence of a metal layer in the surface structure.

Sustainability = concrete actions

FENIX® X-KIN ROSSO JAIPUR BRINA LIMITED EDITION / COURTESY OF ARPA INDUSTRIALE

The thermal healing of superficial micro-scratches and other unique characteristics make FENIX® an extremely durable material. Product durability is indeed the main driver of Arpa Industriale’s entire sustainability policy. The longer the product’s life, the more time is available to mitigate the environmental impact associated with raw material production and the manufacturing process. Not only that: since they involve fewer replacements, long-lasting products result in reduced resource usage, lower pollutant emissions, and less waste compared to shorter-lived goods.

The capitalisation of product and material longevity is part of the company’s corporate sustainability policy since 2010. It has been incorporated into the company’s business plan and can be summarised by the motto “do no harm, do good, do better”.

The objective of such policy is the constant reduction of the environmental impact as measured by the Life Cycle Assessment (LCA) method. This methodology involves measuring key indicators that affect environmental impact throughout the production process. It enables the definition of effective strategies to reduce the company’s overall impact in terms of energy, water, and CO2 emissions. In this respect, Arpa’s most ambitious goal focuses on CO2 emissions, with a 28% decrease by 2026 to successively reach full Carbon Neutral status, which FENIX already achieved in 2021.

CORPORATE PROFILE

Arpa Industriale is an Italian company founded in 1954, operating globally in the interior design materials market. Its high-quality surfaces and innovative materials are produced at its 150,000 sqm plant in Bra, Northern Italy. The company has long been aware of its responsibilities towards all stakeholders, including the broader social and environmental context in which it operates. Arpa Industriale is part of Broadview Holding, a leading global group in surface materials.

arpaindustriale.com

fenixforinteriors.com

FENIX’S MAIN FEATURES

THE TECHNOLOGY BEHIND FENIX®

COURTESY OF ARPA INDUSTRIALE

FENIX® is obtained by the simultaneous application of heat and pressure, in order to achieve a homogeneous, non-porous product with a high density. The core consists of paper impregnated in thermosetting resins. The outer surface is composed of a substrate of paper treated with next generation acrylic resins, applied as a multilayer coating and then polymerised through an Electron Beam Curing process. Observed under a microscope, the structure of FENIX® appears as an irregular landscape of peaks and valleys. When light waves strike this material, the angle of incidence is not equal across the entire surface. Therefore, light is reflected in different directions. This is what makes FENIX so perfectly opaque.

CERTIFICATIONS

FENIX is certified according to current reference standards. Furthermore:

Food contact suitability.

· NSF (National Sanitation Foundation) certifies the material as suitable for food contact.

· Greenguard IAQ confirms that the material excels in low indoor pollutant emissions.

· IMO MED. FENIX NTM (0.9 mm thickness) and FENIX NTA (0.7 mm): both materials are suitable for use on board ships.

· M1 certification according to the Building Information Foundation RTS, verifying the emissions of volatile organic compounds (VOCs) from FENIX when used as a building material.

All rights reserved

.jpg?VGhlIFBlcmZlY3QgU2xvdC1pbijmraPnoa4pLmpwZw==)